rockwell hardness test aluminium|aluminum hardness rating chart : member club Furthermore, the hardness of aluminum alloys can also be measured with specific hardness testers, such as Vickers hardness testers, and the Rockwell hardness testing method. This indicates that the hardness . Está a procura de acompanhantes mulheres na cidade Jundiaí? No Fatal Model você encontra! Veja acompanhantes verificadas próximas de você!

{plog:ftitle_list}

WEBGlazen schuifwanden; Terrasoverkappingen; Overkapping; Veranda; Contact; Informatie. Klantbeoordelingen; Verlanglijst; Mijn account; Hulp nodig? Bel ons op +31 85 130 64 19. Maandag t/m vrijdag van 08:00 t/m 23:59. Zaterdag en zondag van 09:00 t/m 17:00

Furthermore, the hardness of aluminum alloys can also be measured with specific hardness testers, such as Vickers hardness testers, and the Rockwell hardness testing method. This indicates that the hardness .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

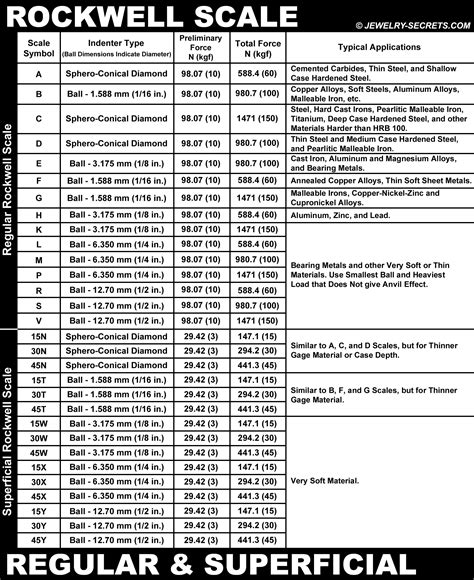

The Rockwell scale is a hardness scale based on indentation .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .

For the longest time I thought that the only way to properly check the hardness of metal was with a proper Rockwell testing machine. Thankfully, I’ve learned a few other methods and tricks over the years that have really made this more . Rockwell hardness does have a relationship to tensile strength in some structural alloys, such as steel and aluminum. The Rockwell hardness test involves making an indentation on the test material. The indenter is either .

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. . the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor loads of 10kgf and major loads of 100kgf. On the other hand, the HRC scale is used for testing hard .Hardness of 6061 Alloy. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 105 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .

An indenter with a hard metal ball or a cone/diamond pyramid is pressed vertically into the surface of the test specimen resting on a solid support. The test load is applied impact-free with . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0 .PDF | On Apr 1, 2020, Armin Yazdanshenas and others published Rockwell Hardness Testing on an Aluminum Specimen using Finite Element Analysis | Find, read and cite all the research you need on .

Brinell hardness of 2024 aluminium alloy depends greatly on the temper of the material, but it is approximately 110 MPa. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 95 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Aluminium is approximately 240 MPa.

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Sheet metal may be too thin and soft to test on a given Rockwell scale without exceeding the minimum thickness and possibly damaging the test window. In this case, a diamond anvil can be used to consistently affect the result.Rockwell Hardness Testing on an Aluminum Specimen using Finite Element Analysis Armin Yazdanshenas#1, Chung-Hyun Goh#*2 #Department of Mechanical Engineering, University of Texas at Tyler

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .

How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . Adding very small amounts of alloying elements to aluminum can increase tensile strength, yield .Aluminum 6061-T6; 6061-T651. Subcategory: 6000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal. Close Analogs: . Converted from Brinell Hardness Value: Hardness, Rockwell B: 60: 60 Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107 Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa:

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for . Rockwell hardness testing is somewhat comparable to Brinell hardness testing, in that it measures a metal’s resistance to penetration, however, it differs in that the depth of the impression is measured, rather than the diametric area in the case of Brinell.Due to its speed and simplicity, as well as the small size of the indentation and its ability to distinguish small .

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . Figure 1: Schematic hardness and conductivity loop showing the relationship of hardness and conductivity to the heat-treated condition of an aluminum alloy. Figure 2: Hardness and conductivity relationships for several different heat treatable aluminum alloys. Hardness of a part is measured using a typical Rockwell “B” hardness tester.

To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale . There are several types of indentation hardness tests, including Brinell hardness, Rockwell hardness, Vickers hardness, and micro-hardness, which differ in terms of the indenter used, the applied load, and the duration of the load. ③ Rebound hardness. Rebound hardness testing is primarily used for metal materials.

Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is employing the correct hardness testing method to show manufacturers their parts achieve design requirements. . Variants on the Rockwell hardness test procedure are used depending on .To increase the surface hardness of the metal part, while keeping the core soft. Mild Steels (1018, A36) . The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a diamond cone indenter) for .1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .

rockwell hardness scale for aluminum

rockwell hardness chart for aluminum

1. 3,95 mi. € Valor de mercado total. Jogadores no plantel: 31. Média etária: 26,4. Estrangeiros: 3 9,7 % Jogadores de Seleção: 0. Estádio: Estadio Roberto Jordán Cuellar .

rockwell hardness test aluminium|aluminum hardness rating chart